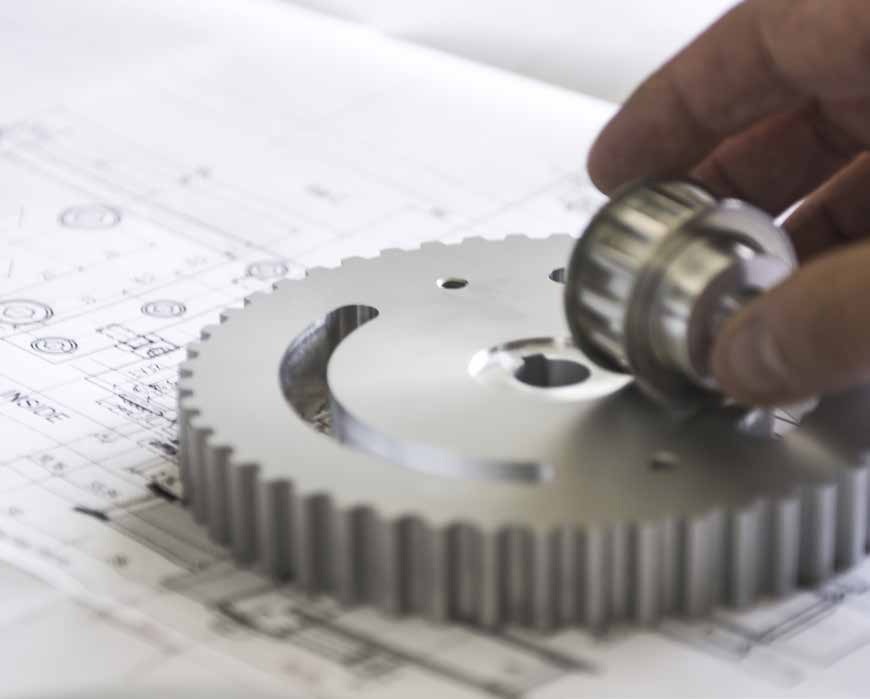

Daring to use micromechanics

Vitrocsa uses more than one thousand exclusive components in its hidden elements, uprights and closure mechanisms, all produced in the same way as high-end mechanical watch parts.

Each part is perfect, ideal for its role, allowing the number of system components to be reduced to a minimum.

The parts are custom-designed and manufactured, then individually fine-tuned before being assembled using precision systems engineering.

Vitrocsa guarantees its products are "zero defect", made to last a lifetime.

OPTIONS

A range of equipment is available as an option:

With an anodised 25 micron natural or coloured aluminium alloy structure, the thermolacquered version is available in an infinite choice of colours.

The frames drain vertically, with the rainwater being collected in a stainless steel chamber. This chamber is equipped with drainage foam to protect against the pressure of the wind. It also houses PVC support components which distribute the loads (weight of the glazing) across the structure.

To clearly demonstrate the properties of the Vitrocsa window, we have conducted standardised tests in an accredited laboratory (SWISS TESTING SERVICE NUMBER STS 317).